Profile Bending Machine

You are here : Homepage Bending Machines Profile BendingFollowing Companies Manufacturing Bending Machines Machine (33 Companies)

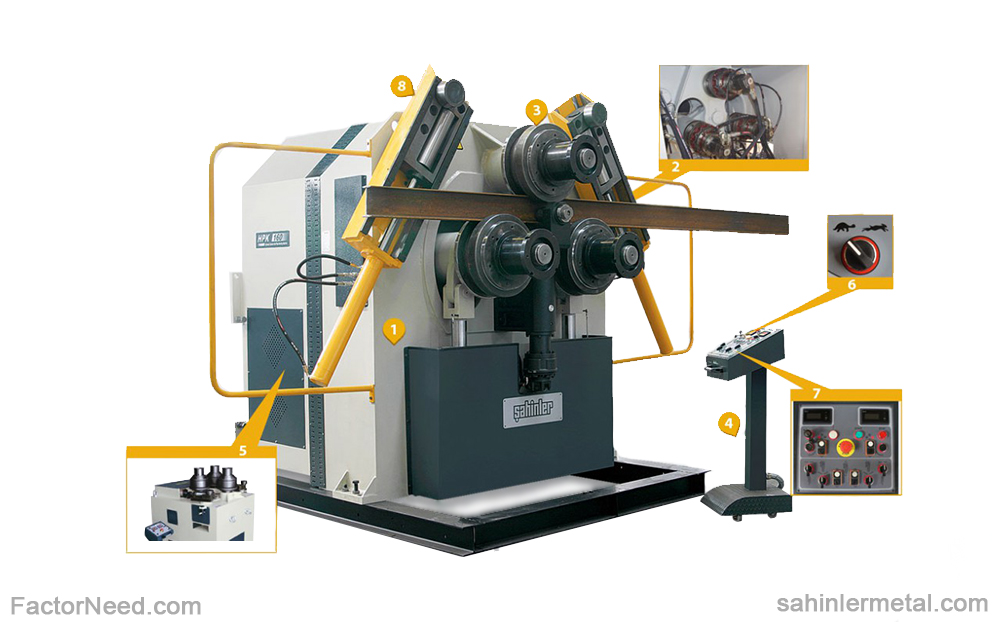

Price of profile bending machine

One of the factors that can be effective in determining the price of profile bending machine is the cross-sectional shape of the profiles, wall thickness, dimensions and their material, which is considered to determine the price of profile bending machines. Another technical point that can play a big role in buying profile bending machines is its bending radius and accuracy.

The brand and the manufacturer of the machine and the equipment and materials used in its construction will also increase or decrease the price of the machine compared to other models and brands in the market.

Auxiliary equipment of profile bending machines such as side rolls, tools to prevent bending of beam edges, tools for fixing or calibrating production screws, etc. and the necessity of using or not using them are also factors that directly affect the price of the machine.

But the point that is sometimes overlooked is business costs. Before purchasing the machine, we should read the letters and commercial laws of that country so that we do not pay additional costs.

14 useful tips for purchasing a profile bending machine:

- The ability to precisely adjust and change the rolls simply and with high accuracy is one of the important points in ordering a profile bending machine.

- Specify the type of ball bearings and their technical specifications along with the maximum allowable pressure.

- The body material used in the construction of the car is very important. Vibration will occur due to slipping at the same time as the rolling operation. The body of the machine can neutralize or reduce the vibration to a minimum.

- The adjustment pressure of the bending rolls can be precisely adjusted.

- Determine the pressure of the hydraulic oil, the type and characteristics of the hydraulic fluid, the material of the pipes and fittings.

- You can determine the need for a hydraulic chamber heater based on the ambient temperature.

- Describe the type and technical specifications of hydraulic jacks.

- If the profile bending machine uses an automated system, specify the brand, model and features required in the numerical control system.

- It is better to send the technical information and brand of high-consumption parts, wires, hydraulic pipes, ball bearings, bending rolls, brand and model of motors, keyboards, etc. to the manufacturer.

- It is recommended to indicate the amount of load that the hydraulic pipes and clamps must withstand.

- Ask the manufacturer of the machine for the electrical circuit diagram of the machine, the hydraulic circuit, the parts list, the connection of the cables, the maintenance manual of the machine and its predicted errors.

- Enter the necessary agreements regarding after-sales services such as transportation, installation, training, replacement and repair warranty, etc. by the manufacturer in writing and have them signed by both parties.

- Describe the environmental conditions of the workplace, including humidity, temperature changes, dust levels, and proximity to other production equipment.

- Write the maximum sound output of the profile bending machine in decibels (DB). Which is generally between 40 and 75 decibels.

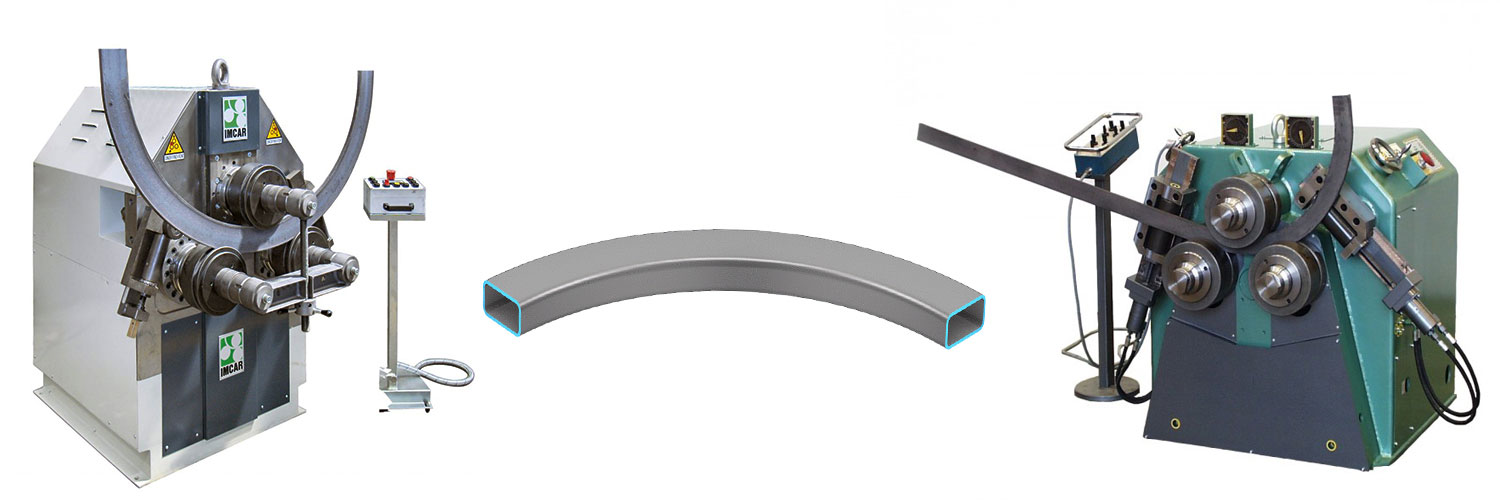

Profile bending machines

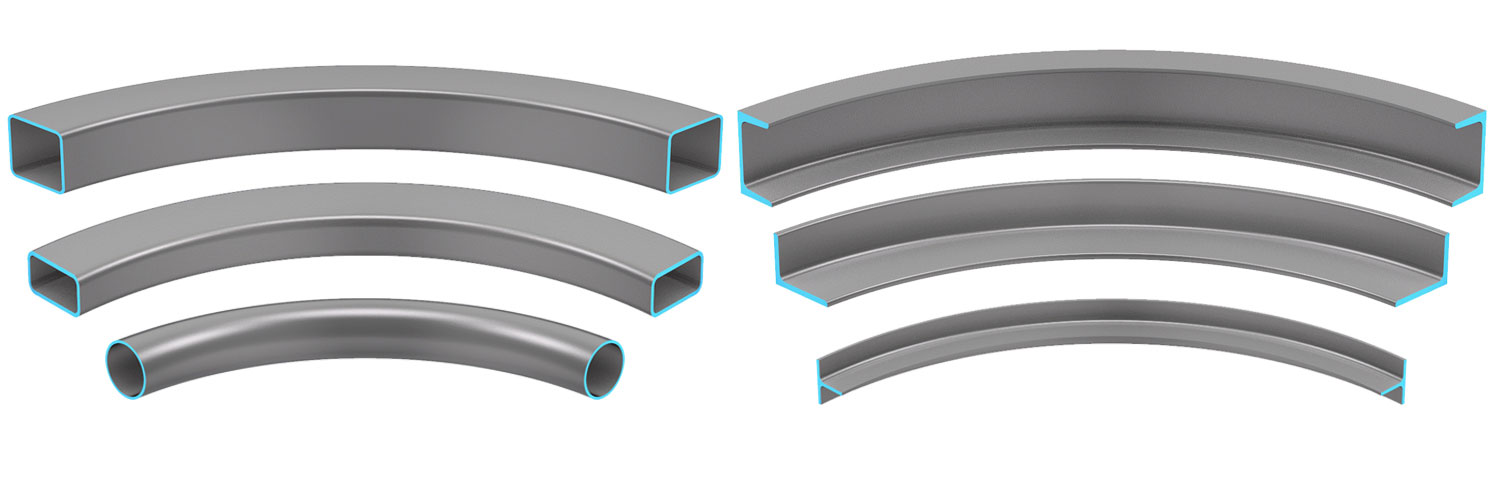

Profile bending machines are used to perform bending process by cold rolling method on profiles with different shapes and sizes. Profile bending machines are commonly used to bend profiles such as pipes, rods, angles, T-shaped profiles, U-shaped profiles and beams.

Profile bending machines are a type of bending machine, bending profiles having different shapes like pipes, rods, corners, T-shaped profiles, U-shaped profiles and beams. The most important part of such devices are the rolls (usually three rolls) which apply a combination of forces on the profile and the result is a shape in the direction perpendicular to the axis of the profile, so they are called angle rolling bending machine or section also called bending machine.

To increase the bending capability, process safety and bending accuracy of the profiles, rolls with different shapes with grooves that match the cross-sectional shape of the profiles are used. To bend profiles with different materials and shapes of different sections, different rolls should be used in the process as the bending parameters get changed with the change of material and the cross-sectional shape of the profiles. It goes without saying to bend aluminum profiles, we have to use aluminum sheet bending machines in the process. Because the material of the rolls and the force exerted on the profiles are different from other profile bending machines.

Profile bending machines are produced in three types: Horizontal profile bending machines, Vertical profile bending machines and movable profile bending machines. The type of condition can be selected according to the type and size of parts.

Applications of Profile bending machines

The Profile bending machines are widely used to produce heavy frames for trucks, frame, metal constructors, water and gas tanks, roof supports, gantry cranes, Transport systems, Window profiles Greenhouses and Roofs over indoor swimming pools

Differences between profile bending machines and pipe bending machines:

As we are able to bend pipes, rods, wires and profiles, the question arises that what the difference is between profile bending machine and pipe bending machine?

The fact is that both machines are able to bend the pipes and profiles in case changing tools in some machines or in some circumstances, but there are some limitations for the profile bending machines as mentioned below:

Due to the structure of profile bending machines; These types of devices are able to create bends with large radii and angles. Also, they do not have the ability to bend short pipes and due to not using PLC, they will not be able to create bends with the desired accuracy. They are not normally equipped with, feeding systems, measuring and mandrel systems. Another question may now arise again whether profile bending machines are more inefficient than pipe bending machines. The answer is no, we have say that there are some limitations for profile bending machines and pipe bending machines and each type is used for specified purposes. We mention briefly some differences as follows:

- Profile bending machines can perform full-circle, semi-circular, and segmental bends well, but they are not able to bend local bends with different radii.

- The profile bending machines are not normally produce three-dimensional bends. The machines mostly can produce two-dimensional bends.

- One of the major limitations of bending machines relates to the lack of variety in bending different sections. Importantly, both types of bending machines could have different performance in different circumstances. The use or non-use of each of these machines depends on items such as the final product (manufactured part), material, accuracy, production capacity (circulation) and other items.

- Profile bending machines are able to bend profiles having lengths up to 50 times more than their diameter but pipe bending machines can bend up to 10 times more than the diameter of the pipe.

- In profile bending machines the driving force to move the rolls is obtained through electric motors so, one of the advantages of the machines is the cheap production. On contrast one of limitations relates the low accuracy in controlling the amount of rotation. It is also less efficient than the motors of other bending machines, and an "inverter" must be used to adjust its speed.

Types of profile bending machines

When it comes to profile bending, we subconsciously think of machines that consist of three or four rolls (one or two moving rolls and two drive rolls), placed vertically and bend the profile.

Given that such profile bending machines have the largest share of production and use in the metal industry, it should be noted that there are different types of them that are similar in function but different in appearance and use. There are also other machines that have the ability to mix profiles but do not fall into this category, which will be discussed below.

The most common profile bending machines in the industry are as follows:

Vertical section profile bending machines (axis of the rolls are horizontal):

Horizontal section profile bending machines (axis of the rolls are vertical):

Universal profile bending machines (horizontal-vertical):

Rectangular pipe and profile bending machines:

These machines have a lot of variety and are widely used in industry due to their ease of use and the lack of the need for a qualified operator.

These machines are vertical (standing) and their rolls (three or four rolls) are placed horizontally on it and are used to bend light to relatively light profiles and in small to medium sizes. These profile benders can bend profiles with different cross sections. To do this, the rolls need to be replaced and the shape of the selected rolls should be similar to the body and the same size as the outer cross-section of the profiles to prevent deformation, possible financial and personal damage. Typically, these machines use a hydraulic system to adjust and create a moving roll pressure on the profile. Also, with adjustable guides on both sides of the machine, bending accuracy and bending angle can be controlled and improved. These machines are automatically and semi-automatically controlled and the intelligent control system used in them is of the MINI PLC type, which has the ability to receive and store various programs.

These machines have the ability to create spiral or spring-shaped bends. They can bend U-T-I-belt and pipe profiles. When buying, you should pay attention to the Auxiliary equipment of profile bending machines that needed to produce the product so that you do not have any problems during production.

Horizontal profile bending machines with vertical rolls are used to bend profiles, beams and heavy belts in large dimensions. This mode is to prevent double pressure on the rolls and the operating system of the machine and to minimize slipping, deformation and side damage.

These types of profile bending machines are generally designed and manufactured in large dimensions and are used for heavy industries such as ship building, construction and dam industries and other related industries. Horizontal profile benders, like their vertical counterparts, use a hydraulic system to adjust and apply moving roller pressure to create the desired bend. These machines also have their own accessories that should be considered when buying.

By adjusting the guide bars installed on the machine, the bending angle is changed and two-dimensional and three-dimensional bends are created. Spiral bends can even be created using the side tool.

The bending power of these profile bending machines is higher than the others, so that profiles, beams and huge pipes can be bent.

The head of the universal bending machine is adjustable and can be placed both horizontally and vertically. These machines are generally made in small to medium sizes because they are portable and can bend a wide range of profiles with different cross sections. Another feature of these machines, in addition to changing the angle of the head, is changing its rolls, which is done according to the shape and size of the profiles.

Simplicity in operation, no need for a professional operator and high speed of operation are the features of this type of profile bending machines. Universal profile bending machines have the ability to create spiral bends in both vertical and horizontal positions and are used both manually and semi-automatically. The semi-automatic universal profile bending machine uses the MINI PLC intelligent control system, which has the ability to receive and store different bending applications.

This series of profile bending machines are quite similar to pipe bending machines with circular cross section. Although at first glance their distinction is not obvious, however, there are differences between these two types of bending machines.

Molds, holders, mandrels, servo motor power and hydraulic system are different from the tube bending machines mentioned earlier.

Can we use one profile bending machine to bend different materials?

The answer is not always. In order to push the piece forward during bending, rolls with ribbed surface are used. These types of rolls are used to bend steel and iron parts. Meanwhile, for bending soft metal parts and stainless steel pipes, rolls with compressed plastic and without ribbed surface get used.

The following conditions are considered in the optimal and safe purchase of a profile bending machine:

The first step in purchasing a bending machine is to prepare work drawings and technical specifications of the final products.

One of the factors that can be effective in determining the price of profile bending machines is the cross-sectional shape of the profiles, wall thickness, dimensions and their material, which is considered to determine the price of profile bending machines. Another technical point that can play a big role in buying profile bending machines is its bending radius and accuracy.

All the above information along with the text of the request will be sent to the manufacturer in the form of a work plan. After reviewing the request by the manufacturer of the profile bending machine, the desired machine will be offered along with the technical specifications. At this stage, according to the technical specifications of the machine and your expectations from the final product, you can check the technical specifications of the machine and change it if necessary. The resulting changes will be sent to the manufacturer according to the application form and final agreements will be made.

The point to be considered is to send the details and expectations of the device and the relevant process to the manufacturer, which should be unambiguous and completely clear. Details such as mechanical parts, hydraulic parts, electronics and whatever.

Paying attention to the maximum bendable length, the rolling speed of each roll separately to compensate for the difference in speed of the rolls, independence or non-independence of the hydraulic motors of the rolls, the amount of hydraulic pressure is information that can help you buy a right profile bending machine . Also consider the material of the rolls, the appearance of the rolls and their coating, the degree of strength and the critical point of failure.

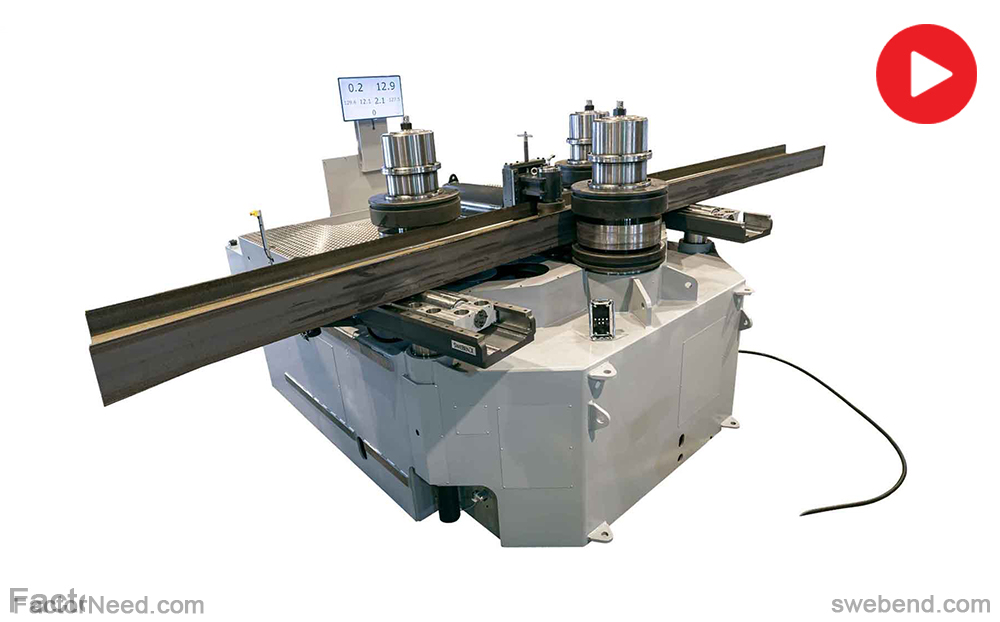

Tecnocurve Company:

Gasparini is one of the leading manufacturers of roll forming machines. Roll forming machines made by this company can be suitable options for creating a variety of profiles with a thickness between 0.2 to 12 mm. In the video below, you can see one of the roll forming machines made by this company, which is integrated with the punching and cutting machine.